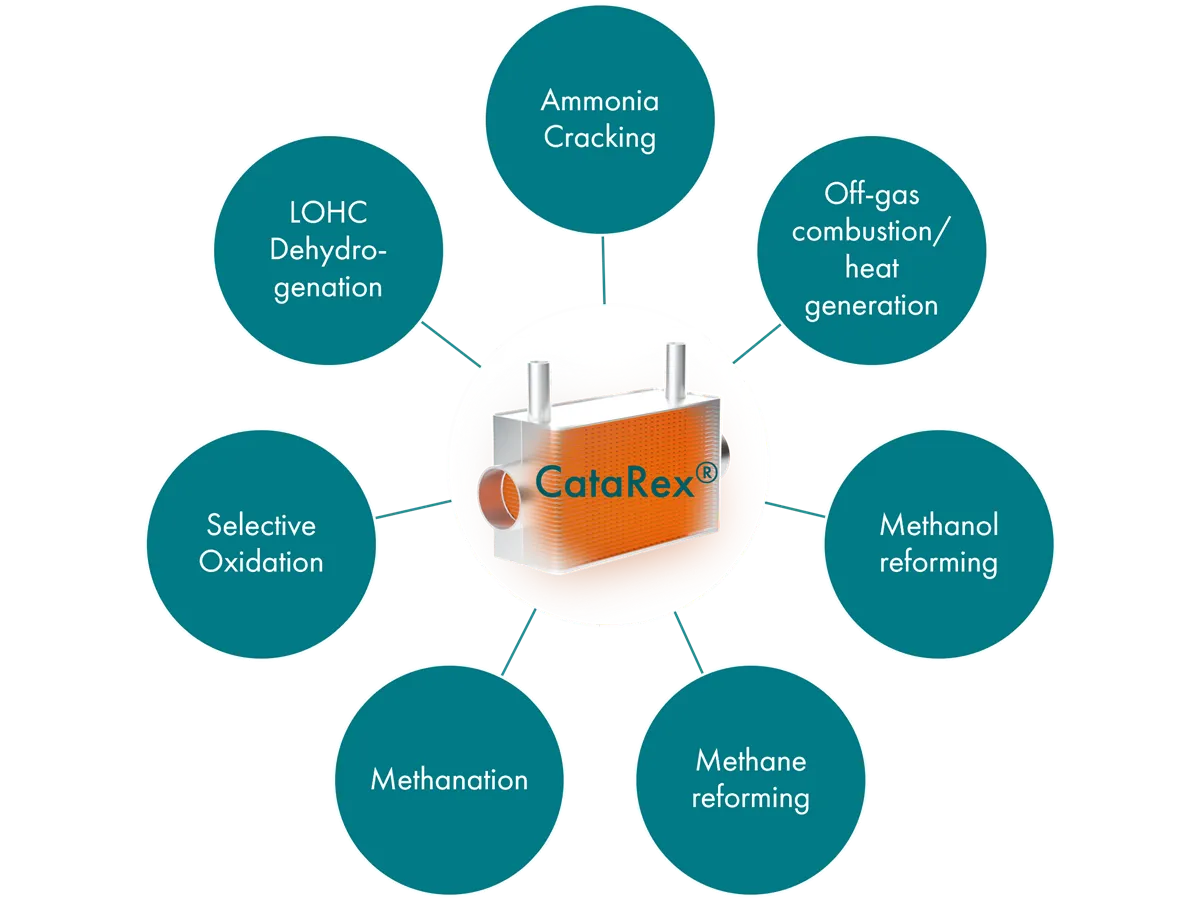

The CataRex® Technology Platform is Catator’s core reactor design – a Catalyzed Heat Exchange Reactor that integrates catalytic reactions and heat exchange in a single compact system. By combining combustion on one side of a heat exchanger with catalytic reactions on the other, CataRex® enables unmatched efficiency, compactness and flexibility.

At its core, the CataRex® reactor uses shell-and-tube or shell-and-plate geometries, coated with Catator’s proprietary CataLite® Coatings. Combustion provides heat on one side, which directly drives catalytic reactions on the other. This close thermal coupling allows both exothermal and endothermal reactions to occur side by side – intensifying processes and saving space.

With a limited set of off-the-shelf geometries, CataRex® can be scaled and adapted to meet a wide range of flow and power requirements. Reactor modules are built using tube bundles or plate stacks, which can be arranged in parallel to increase capacity. At the same time, catalyst formulations are tailored to each specific process – from ammonia cracking to methanol reforming – ensuring optimal performance in every application.

The CataRex® Technology Platform serves as the foundation for Catator’s CataLite® product families:

By enabling process intensification, reduced reactor size and enhanced thermal efficiency, CataRex® supports a wide range of applications in the Power-to-X (P2X) and X-to-Power (X2P) ecosystem.

For customers and partners, CataRex® offers:

With more than three decades of catalytic expertise, Catator has developed CataRex® into a proven, off-the-shelf technology platform that accelerates the transition to a sustainable, hydrogen-based energy system.

Image 1. CataRex® Technology Platform enables a wide range of catalytic applications – from ammonia cracking and methanol reforming to off-gas utilization and synthetic fuel production.

Den här webbplatsen använder cookiesför statistik och användarupplevelse.

Catator AB använder cookies för att förbättra din användarupplevelse, för att ge underlag till förbättring och vidareutveckling av hemsidan samt för att kunna rikta mer relevanta erbjudanden till dig.

Läs gärna vår personuppgiftspolicy. Om du samtycker till vår användning, välj Tillåt alla. Om du vill ändra ditt val i efterhand hittar du den möjligheten i botten på sidan.